We perform experiments both in our home lab location (1223 MEL, 105 S Mathews Ave) and at the Beckman Institute for Advanced Science and Technology (405 N Mathews Ave).

Imaging Modalities

The first step in measuring structural or mechanical properties of bone and soft tissues is to acquire 2D images or 3D image volumes of our samples or subjects. Depending on the type of tissue, sample dimensions, and specific property to measure, there are several imaging options. The three most common imaging modalities in our lab are magnetic resonance imaging (MRI), x-ray computed tomography (CT), and high-speed camera imaging.

|  |  |

Magnetic Resonance Imaging (MRI) | X-ray Micro-computed Tomography (μCT) | High Speed Camera |

| When a doctor suggests you have an MRI, what they are actually saying is that they want a powerful magnet to create a magnetic field in your body, causing all of your molecules to align in one direction. Once aligned, radio waves are sent through your body, momentarily forcing the molecules out of alignment. The time required for the molecules to realign to the magnetic field, as well as other physical parameters, are used to produce images of your body’s internal structure. | We use x-ray computed tomography to create images of a sample through x-ray absorption of its different regions. Clinical CT scans have lower resolution and radiation, which makes them better suited towards in-vivo scans. X-ray micro-computed tomography (pictured above) has higher radiation and resolution, which allows us to visualize complex structures at micro length scales. If you want to imagine this length scale, think of taking a picture of the thickness of a sheet of paper! | We use high-speed cameras similar to your cell phone camera, except that they can record at hundreds of frames per second, they contain more detail (better resolution), they perform better in a wide range of lighting conditions and they have better depth of field. These improvements enable the acquisition of more accurate and smoother data, and ultimately, better scientific results. |

| Applications: MRI is well suited for imaging soft tissues such as ligaments, muscles and tendons. | Applications: Airport security and dentistry use clinical CT scans. We use μCT for bone samples a few millimeters in length. | Applications: Imaging objects during deformation (see: DIC/DVC), or tracking joint movement (see: motion capture). |

Image Processing and Analysis

Once 2D images or 3D image stacks are acquired, we process and analyze the images. Fortunately, we use the Vis Lab at the Beckman Institute, which supports a variety of visualization research, including 2D and 3D image analysis and quantification, 3D animation, high-resolution 2D scanning, and additional capabilities in support of imaging.

|  |  |

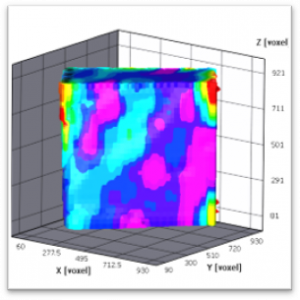

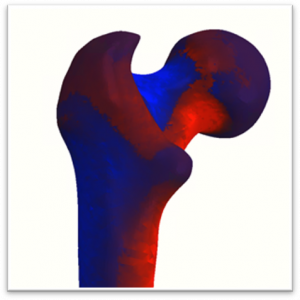

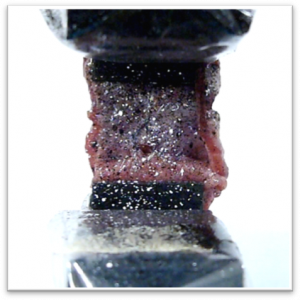

Digital Image/Volume Correlation (DIC/DVC) | Finite Element (FE) Modelling | Image Filtering & Segmentation |

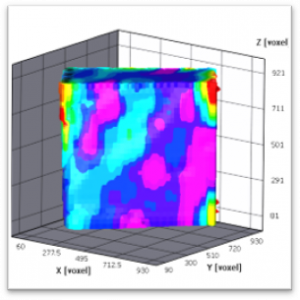

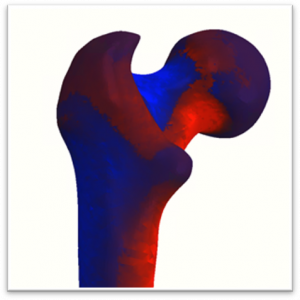

| DIC and DVC are optical methods that tracks patterns through a sequence of 2D images or 3D image volumes, respectively. A 2D pattern can be applied manually to an object using speckled paint, marker dots, or even glitter. In order to track the pattern in 3D, there must be naturally occurring and trackable features within the sample. Thankfully, bone is one of the few materials that has a naturally occurring internal structure that is well suited for 3D pattern tracking. | In engineering, we seldom have textbook equations that are applicable to our exact experimental conditions. We instead take our sample and digitally divide it into thousands (and sometimes even millions!) of little cubes or triangles (called finite elements), which are significantly easier to analyze! Depending on the number of elements, these models take minutes or days to solve. FE modeling is a critical tool that saves experimental time and resources. | Once we acquire image stacks (see: imaging modalities above), the work is far from finished. Often these images are filled with noise or soft tissues that are not of interest. Our job is to “segment” the good data from the “bad” or unwanted data. Segmentation can be performed in 2D images or 3D image stacks, either manually or using automated software, depending on the complexity of the data. |

| Applications: DIC is used across many industries to calculate how samples move over time. DVC is limited to materials such as bone, foams, and composites due to their naturally occurring internal structures. | Applications: Used across many industries. For our group, we make models of whole bone samples, small bone samples, whole joints, tissues, and so much more. | Applications: Segment soft tissue or phantoms from bone scans. Filter noise from CT or MRI image volumes. |

Data Acquisition

Besides imaging, there are lots of other forms of data, both in-vivo and ex-vivo, that our lab acquires and analyzes. We gather motion capture, electromyography (EMG), and force plate data on a variety of subjects and animals and use the data to develop musculoskeletal models to answer some of the questions described above.

|  |  |

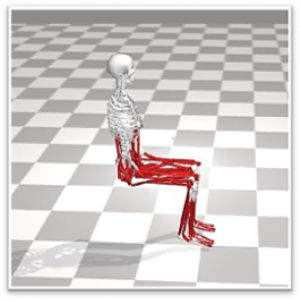

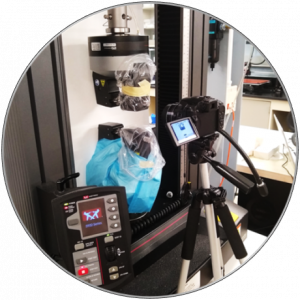

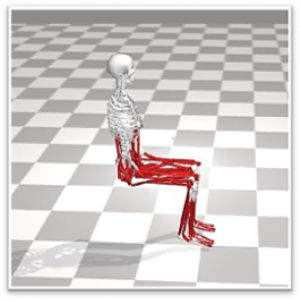

Motion Capture | Mechanical Testing | Musculoskeletal Modeling |

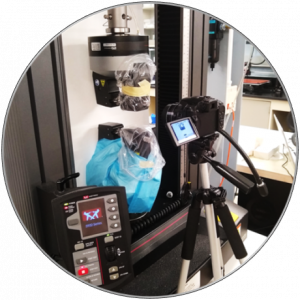

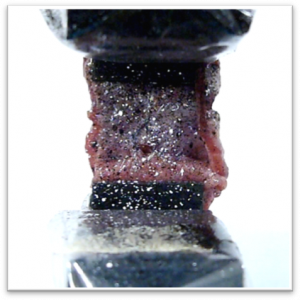

| We attach visible markers to a subject in order to measure three-dimensional kinematics in real time (i.e. motion). These markers send a non-invasive, wireless signal to one or several cameras. Markers attach to each other via small flexible cables or are mounted on small rigid bodies (such as your bones). Our research-grade motion capture system has an accuracy of up to 0.1 mm! | A mechanical testing machine measures the tensile, compressive, and shear properties of biological tissues. We choose to either control the displacement and measure the force or control the force and measure the displacement. The maximum force and displacement, as well as the relationship between force and displacement are some of the most frequent mechanical properties reported in any field of study. | By scaling the motion capture data (see previous section) to a simplified human model, we model, simulate, and analyze the entire musculoskeletal system. For example, we create dynamic simulations of subjects performing daily activities or horses trotting in a field. Further, we calculate the forces in your muscles and joints by including force plate data in the musculoskeletal models. |

| Applications: Track 3D joint movement of humans, sheep, rats or horses. | Applications: Compare the strength of biological materials under tension, compression and bending. | Applications: Simulation of activities such as walking, running, trotting, stair climbing, etc. |

Machine Tools

We perform several cutting and polishing steps to ensure our samples produce consistent data and minimal variability.

|  |  |

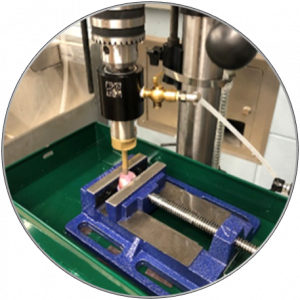

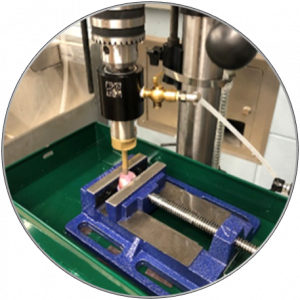

Diamond Saw | CNC Mill | Drill Press |

| Most people know that a saw has hard toothed edges used to cut through a material. But did you know that diamond saws are used for hard or abrasive materials such as glass and ceramics? These materials have surprisingly similar properties to bone, making diamond an ideal material for cutting bone samples. | One of the most common machining processes, our computer numerical control (CNC) mill uses rotary cutters to remove material from a workpiece. Our CNC mill has 5 degrees of freedom (DOF), which works well for complicated sample geometries. We also use the 5 DOF CNC to rotate and translate biological tissues. | A drill press creates cylindrical samples from larger pieces by lowering a rotary cutter onto the sample. Cylindrical samples are desirable for their ease of use in imaging and mechanical testing. |

| Applications: Cutting bone and other tissues into rectangular samples. | Applications: Machining or manipulating samples with 5 DOF | Applications: Cutting bone into cylindrical samples. |